Posts

10 Best Plastic Cut to Size Solutions for Your Projects?

In the world of manufacturing and DIY projects, "plastic cut to size" plays a crucial role. Choosing the right plastic solutions can make a significant difference in your project's success. Expert David Miller, a leader in the plastic fabrication industry, once said, "Precision in plastic cut to size is key for both aesthetic and functional integrity." This statement resonates with project managers and enthusiasts alike.

Plastics come in various forms, each with unique properties. Custom-cut solutions cater to specific needs, reducing waste and ensuring efficiency. Many professionals overlook this aspect, often opting for standard sizes that may not fit their requirements. This can lead to frustration and delays in projects.

Moreover, understanding the types of plastics available and their applications is essential. It is not just about cutting plastic; it’s about choosing the right material that aligns with your project vision. The journey to find the best plastic cut to size solutions is filled with considerations and choices that determine the outcome.

Overview of Plastic Cut to Size Solutions in Various Industries

Plastic cut to size solutions play a crucial role across various industries. These solutions cater to specific needs, from construction to medical applications. According to recent industry reports, the demand for custom-cut plastics is growing at a rate of 6.4% annually. This increasing demand highlights the importance of precision and customization in projects.

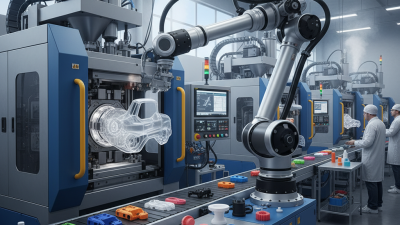

In the automotive industry, plastic components are cut to size for interiors and exteriors. Many manufacturers rely on specific measurements to ensure proper fit and function. A report shows that nearly 30% of automotive weight now comes from plastics. This shift emphasizes the need for lightweight yet durable materials.

The healthcare sector requires exact sizes for surgical instruments and medical packaging. Each component must fit seamlessly to ensure safety and effectiveness. Research indicates that personalized medical solutions can reduce production costs by up to 15%. Every detail matters here. Yet, some challenges remain, such as waste generated from cutting processes. Continuous improvement in cutting technologies is essential.

10 Best Plastic Cut to Size Solutions for Your Projects

| Material Type | Thickness (mm) | Cutting Method | Applications | Lead Time |

|---|---|---|---|---|

| Acrylic | 2 - 15 | Laser Cutting | Signage, Displays | 1 Week |

| Polycarbonate | 3 - 10 | CNC Machining | Safety Shields, Windows | 2 Weeks |

| PVC | 1 - 20 | Saw Cutting | Plumbing, Electronics | 3 Days |

| PETG | 2 - 12 | Laser Cutting | Packaging, Displays | 1 Week |

| HIPS | 1 - 5 | Thermoforming | Food Packaging, Retail | 5 Days |

| Nylon | 4 - 20 | CNC Milling | Mechanical Parts, Gears | 2 Weeks |

| Delrin | 5 - 30 | CNC Turning | Automotive, Industrial | 3 Weeks |

| PTFE | 2 - 10 | CNC Cutting | Seals, Gaskets | 2 Weeks |

| Polypropylene | 1 - 12 | Die Cutting | Containers, Parts | 1 Week |

Key Considerations for Selecting Plastic Materials for Custom Cuts

When selecting plastic materials for custom cuts, several factors should be considered. The intended application of the plastic is crucial. Different projects may require specific properties. For instance, some applications demand high impact resistance, while others may focus on clarity. Understanding your project’s needs is essential.

Thickness is another critical factor. Thinner materials can flex and bend easily. However, they may not withstand heavy loads. On the other hand, thicker plastics are more robust but can be difficult to manipulate. Think about the balance you need. The cutting method will also influence your choice. Not all plastics can be cut using the same tools.

Lastly, consider the aesthetic qualities. Color and finish can affect the final look of your project. Some plastic types take paint better than others, creating potential challenges down the line. In this regard, experimentation might be necessary. Take note of your findings and adjust your approach as needed. It's a learning process, and each project will teach you more about the materials you choose.

Comparing Cost-Effectiveness of Different Plastic Cutting Techniques

Selecting the right plastic cutting technique can significantly impact your project's cost-effectiveness. A recent industry report indicates that choosing the appropriate cutting method can reduce waste by up to 30%. Not all techniques are equal in efficiency or affordability. For instance, laser cutting may deliver precision but comes with higher operational costs.

In contrast, methods like die cutting offer a more budget-friendly option for larger production runs. This can save businesses upwards of 20% compared to laser methods. However, it might not be ideal for intricate designs. Mechanical cutting methods, while economical, often result in more material wastage. This can lead to higher overall expenses, especially in projects requiring custom sizes.

Investing time to evaluate each method's pros and cons is essential. Many businesses underestimate the long-term savings achievable through thoughtful material choice and cutting strategies. Engaging experienced professionals can further ensure that your chosen method aligns with your project's specific needs and budget constraints.

Cost-Effectiveness of Plastic Cutting Techniques

Industry-Specific Applications for Cut to Size Plastic Solutions

Cut to size plastic solutions cater to various industries, offering customized benefits that enhance operational efficiency. In the construction sector, specific-sized plastic panels are used for insulation and façade applications. These panels can improve thermal performance by up to 30%. This significant energy saving appeals to builders looking to meet sustainability goals.

In the medical industry, cut to size plastics are crucial for creating custom barriers and equipment casings. The healthcare sector values materials that can be easily sanitized. Reports indicate an 18% growth in demand for tailored medical-grade plastics. Despite this need, ensuring consistent quality remains a challenge. Variations in manufacturing can lead to inconsistencies that affect patient safety.

The automotive industry increasingly adopts cut to size plastics for lightweight components. Lighter materials improve fuel efficiency by 10-15%. However, balancing weight and strength presents a dilemma for manufacturers. They must find solutions that do not compromise safety standards. Industry surveys show that 40% of manufacturers cite this as a major hurdle in production.

Environmental Impact and Sustainability of Plastic Cutting Processes

Plastic cutting processes have a significant environmental impact. The methods used to cut plastic often lead to waste. Excess material can accumulate, creating a burden on landfills. Despite efforts to recycle, not all plastics are reused effectively. This raises questions about the sustainability of plastic production and disposal.

Recyclable options exist, but they are not always implemented. Cutting processes may generate microplastics that escape into the environment. These tiny particles can harm ecosystems and wildlife. We need to reflect on our choices and consider alternatives where possible.

Innovative cutting technologies aim to reduce waste. Techniques like CNC routing minimize excess material. However, they may require energy-intensive machinery. Balancing efficiency and sustainability is complex. Awareness and responsible practices can lead to improvements, but the journey is ongoing.

Related Posts

-

2026 Top Trends in Plastic Fabrication Innovations and Applications?

-

2026 Best Plastic Sheet Cut to Size Options for Your Projects?

-

Exploring the Versatility of Clear Plastic Sheets: 10 Innovative Applications Backed by Industry Insights

-

Top 10 Best Plastic Panels for Your Home and Garden?

-

Top 10 Best Plastic Injection Molding Techniques for Efficient Manufacturing?

-

10 Best Plastic Injection Techniques for Optimal Manufacturing Efficiency