Posts

What are the Best Plastic Molding Machines of 2026?

The demand for plastic molding machines is set to rise in 2026. The global plastic molding machine market is projected to reach $40 billion by 2028, according to industry reports. This growth reflects the increased need for customization and efficiency in various sectors.

In today’s competitive landscape, manufacturers face rising expectations. Consumers demand high-quality products with shorter lead times. The right plastic molding machine can greatly influence production speed and material efficiency. Companies must evaluate their choices carefully to stay ahead.

However, many might overlook crucial aspects of these machines. Maintenance is often neglected, leading to downtime and increased costs. Furthermore, not all machines cater to specific needs effectively. Thus, a thorough understanding is essential when selecting the best option. This article aims to explore the top choices for plastic molding machines in 2026, offering insights and critical reflection on each model.

Overview of Plastic Molding Machines: Types and Functions

Plastic molding machines play a vital role in the manufacturing industry. They transform raw plastic material into different shapes and forms. This technology is essential for producing various products, from toys to automotive parts. Understanding the types and functions of these machines can enhance your production process.

Injection molding is one of the most common types. It involves injecting molten plastic into a mold. This method is widely used for its efficiency. Another type is blow molding. It is primarily used for creating hollow objects. This includes bottles and containers. Each method has unique advantages and applications in manufacturing.

Tips: When choosing a molding machine, consider your production volume. High-volume needs may require advanced machines. Regular maintenance is crucial, too. Neglect can lead to breakdowns. This affects production timelines and costs. Lastly, stay informed about technological advancements. They can drastically improve efficiency and quality.

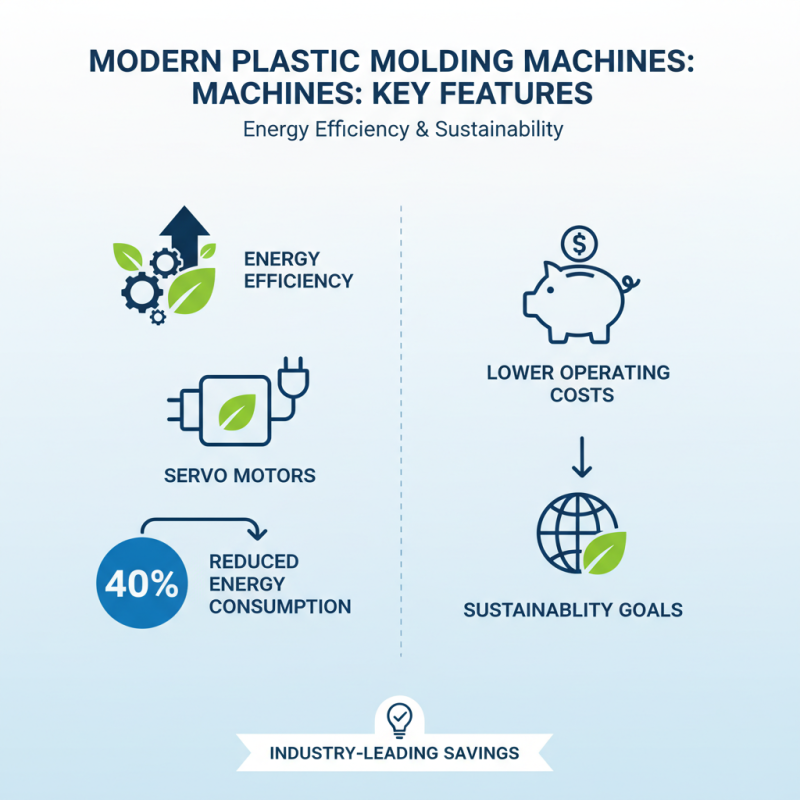

Key Features to Consider in Modern Plastic Molding Machines

When evaluating modern plastic molding machines, several key features stand out. Energy efficiency is paramount. According to recent industry reports, machines with servo motors can reduce energy consumption by up to 40%. This not only lowers operating costs but also aligns with sustainability goals.

Precision control is another critical aspect. Advanced machines now utilize closed-loop systems to ensure accurate molding. This minimizes waste and improves product quality. Statistical data indicates that precision molding can increase production yield by as much as 30%. However, achieving this precision requires a high initial investment. Many companies hesitate, which may lead to inefficiencies in the long run.

Durability should also be considered. Plastic molding machines face wear and tear over time. Regular maintenance is crucial, yet it's often overlooked. A lack of routine checks can result in production delays. This is a common issue in the industry that demands attention. Investing in better materials and technology enhances longevity but requires upfront resources. In summary, manufacturers must balance cost and quality while staying attuned to market trends.

Top Brands Leading the Plastic Molding Machine Market in 2026

In the rapidly evolving landscape of plastic molding machines, several brands stand out as leaders for 2026. The market is expected to grow significantly, driven by innovations in technology and material efficiency. Research suggests a

compound annual growth rate (CAGR) of 5.4% from 2021 to 2026, with energy-efficient machines gaining traction.

Manufacturers are focusing on automation and smart features, which streamline production processes. Reports highlight that 64% of industry players prioritize sustainability in their machine designs. Adapting to eco-friendly practices is now a necessity.

However, not all companies are keeping pace. Some lag behind, struggling with outdated technology. This gap creates an opportunity for those who can innovate quickly.

Quality assurance remains a challenge in this sector. The inconsistency in machine performance can lead to production halts. Achieving precision is paramount, yet many units still fall short. A recent survey indicated that 30% of users reported dissatisfaction with output quality. It’s clear that while advancements are promising, there is a pressing need for brands to address these ongoing issues.

Innovations and Technologies Shaping the Future of Plastic Molding

In 2026, plastic molding technologies are transforming. Innovations in materials and processes are leading the charge. Advanced machinery is more energy-efficient. Techniques like multi-material molding are gaining traction. These developments reduce waste significantly.

Tips: Consider energy source. Solar and wind options can help cut costs. Evaluate if your materials are recyclable. This will improve sustainability.

The integration of smart technology is revolutionizing molding machines. IoT devices allow real-time monitoring. Data analytics enhances efficiency. Yet, these systems can be complex. A skilled workforce is crucial to navigate these advances. Without proper training, mistakes can occur. Workers must adapt constantly.

Tips: Regular training sessions are essential. Encourage your team to stay updated on industry trends. Emphasize the importance of quality checks. This helps reduce errors and rework in production.

Comparison of Performance Metrics in Leading Plastic Molding Machines

When exploring the best plastic molding machines of 2026, performance metrics play a crucial role. These metrics include energy efficiency, cycle time, and output quality. Energy efficiency is key for cost savings in production. Machines with advanced servo motors often achieve superior energy use. However, not all machines maintain efficiency at high speeds.

Cycle time measures how quickly a machine completes its tasks. Some leading machines report impressive cycle times but struggle with consistency. Variation in material types can also affect these results. Output quality is another significant metric. The best machines produce consistent, defect-free parts. Yet, even top models may have slight imperfections that require adjustments.

Investing in new technology is exciting but often comes with challenges. User interfaces can be complex at first. Training operators to use advanced features may take time and trial. Reflection on past experiences with less efficient machines can inform better choices now. Balancing performance with usability remains a vital consideration for manufacturers.

Related Posts

-

Why is Plastic Fabrication Important for Modern Industries?

-

2026 Top Trends in Plastic Fabrication Innovations and Applications?

-

Top Plastic Parts Innovations in Modern Manufacturing?

-

2026 Best Plastic Sheet Cut to Size Options for Your Projects?

-

Revolutionizing Product Design with Advanced Plastic Prototype Manufacturing Techniques

-

What is a plastic molding machine and how does it work?