Posts

2026 Best Plastic Sheet Cut to Size Options for Your Projects?

In today's dynamic world of DIY projects, having the right materials is crucial. One popular choice is the "plastic sheet cut to size." Industry expert Mark Davies emphasizes, “Finding the perfect size can save you time and increases efficiency.” This statement reflects the importance of precise measurements when selecting plastic sheets.

Plastic sheets come in various sizes and thicknesses, making them versatile for many applications. However, customers often face choices that can be overwhelming. Each project requires specific dimensions and types of plastic, leading to potential mistakes if not adequately addressed. Miscalculations can lead to wasted materials and frustration.

As projects evolve, the need for customizable plastic sheets becomes increasingly apparent. While some options provide pre-cut sizes, tailored solutions often yield better results. Reflecting on your needs and preferences can enhance your experience with plastic sheets. The right choice can be the difference between a successful project and a troublesome ordeal.

Overview of Plastic Sheet Materials for Custom Cutting

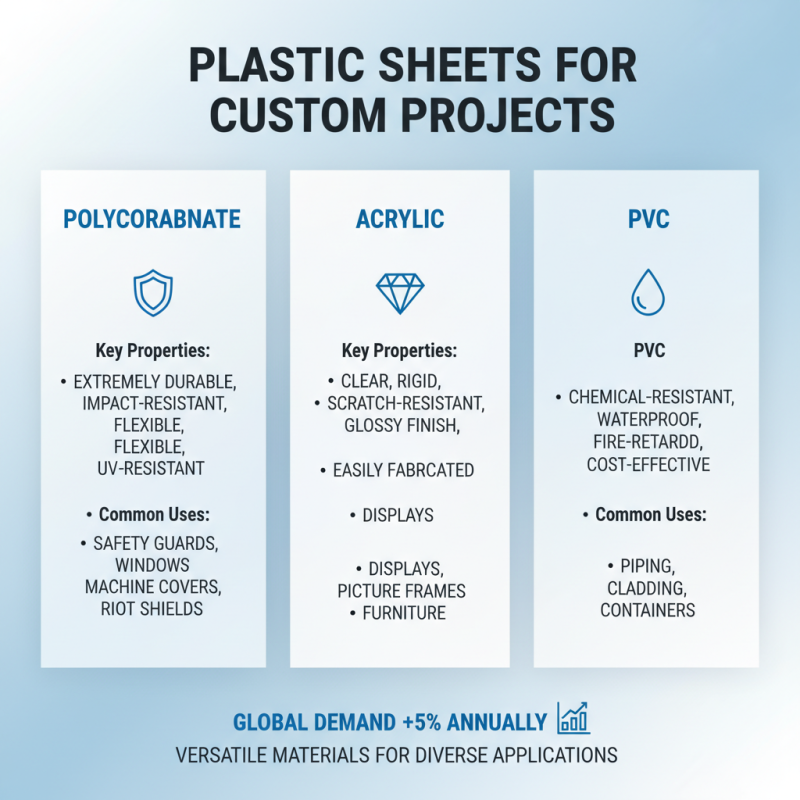

When considering plastic sheets for custom projects, it's crucial to understand the different types available. Polycarbonate, acrylic, and PVC are among the most popular materials. According to industry reports, the global demand for these versatile sheets has increased by over 5% annually. Each material offers unique properties, catering to diverse applications.

Polycarbonate sheets, for instance, are particularly strong yet lightweight. They can withstand heavy impacts, making them ideal for protective applications. In contrast, acrylic sheets are prized for their clarity and can be easily formed. However, they scratch more easily than polycarbonate. This can lead to issues in high-traffic areas.

PVC sheets offer flexibility and durability but can warp under high heat. This limitation may necessitate the careful consideration of application environments. When custom-cutting these materials, precise measurements are vital. A slight error can affect the overall fit and function of a project. Many professionals agree that choosing the right type and size ensures the success of your designs. Each material's characteristics should guide decisions in project planning.

Types of Plastic Sheets: Acrylic, Polycarbonate, PVC, and More

When choosing plastic sheets for your project, you'll likely encounter various types: acrylic, polycarbonate, and PVC are among the most popular options. Each type has unique properties suited to different applications. Acrylic sheets are lightweight and shatter-resistant. They offer excellent clarity, making them great for displays. Polycarbonate is even stronger; it withstands impact better than glass. PVC sheets are affordable and versatile, ideal for signage and other applications.

Here are some tips: Always assess your project requirements. Consider factors like durability, weight, and clarity. This will help refine your options. Acrylic might be perfect for a decorative piece, while polycarbonate could be better for safety-focused applications. Don't skip testing smaller samples before making larger purchases. This gives you a sense of the material's suitability.

Also, think about the environment where the sheets will be used. Some materials can degrade under UV light. For outdoor projects, UV-resistant options are essential. Remember, a well-informed choice saves time and resources in the long run. Each type has its imperfections, and understanding these can lead to better decisions.

Factors to Consider When Choosing Plastic Sheets for Projects

Choosing the right plastic sheets for your projects involves several important factors. First, consider the thickness you need. A thicker sheet offers more durability but can be harder to work with. Thinner sheets may be easier to cut but might not withstand impact as well.

Material type is also crucial. Acrylic and polycarbonate are popular choices. Acrylic is lighter and easier to handle. However, polycarbonate provides excellent strength and is less prone to shatter. Weigh your options based on the specific requirements of your project.

Tips: Measure your workspace accurately before purchasing. You don’t want to end up with oversized sheets. Always check for UV resistance, especially for outdoor projects. This can prolong the life of your plastic. Lastly, don’t hesitate to request samples. Physical testing can reveal more than just specs online.

Top Suppliers Offering Cut-to-Size Plastic Sheet Options

When searching for plastic sheets cut to size, several suppliers stand out for their services. These companies cater to various project needs, from crafting to building. They offer an array of materials, including acrylic, polycarbonate, and PVC. Finding the right thickness and finish can be tricky. Many suppliers provide options based on your specifications, but not all may meet your exact needs.

One drawback is that while the selection is broad, the clarity of the sheet might vary. Sometimes, the perfect size does not equate to the perfect quality. It’s wise to request samples before making a bulk order. This can prevent disappointment later. Additionally, turnaround times may differ significantly among suppliers. Some may promise quick processing, yet delays can occur. Always verify these timelines beforehand.

Exploring local suppliers can be daunting. Availability might limit your choices, and shipping fees could unexpectedly increase costs. It’s essential to balance quality with budget constraints. For those taking on DIY projects, researching multiple options is key. Each supplier has its strengths and weaknesses. Finding the best fit for your project may take time and effort, but the right choice can lead to satisfying results.

Applications of Custom Cut Plastic Sheets in Various Industries

Custom cut plastic sheets are transforming various industries. In healthcare, these sheets are used for protective barriers. A report from the Plastics Industry Association states that the sector consumes over 4 billion pounds of plastic annually. Customization allows for precise dimensions, which help in maintaining cleanliness and reducing contamination.

In construction, plastic sheets serve multiple purposes. They are used for insulation, sheathing, and as vapor barriers. The Global Construction Plastics Market is projected to reach $70 billion by 2027. Workers often face challenges with standard sizes. Custom cuts can minimize waste and improve efficiency on site. However, it requires careful planning and measurement.

Retailers and manufacturers benefit as well. Display cases often use custom plastic sheets to enhance visibility. The right dimensions can attract more customers. Yet, when poorly cut, gaps may form, negatively affecting aesthetics. Balancing quality and affordability remains a constant struggle. Choosing the right thickness is crucial too, as it impacts durability and handling.

Applications of Custom Cut Plastic Sheets in Various Industries

Related Posts

-

Exploring the Versatility of Clear Plastic Sheets: 10 Innovative Applications Backed by Industry Insights

-

Top 10 Best Plastic Panels for Your Home and Garden?

-

2026 Top Trends in Plastic Fabrication Innovations and Applications?

-

What is Plastic Prototype Manufacturing? Benefits and Key Processes Explained

-

Transform Your Space with Clear Acrylic Solutions for Modern Decor

-

2025 Top 5 Colored Acrylic Sheets for Stunning Home Decor and DIY Projects