Posts

2026 Best Plastic Sheets for Every Use Guide?

In recent years, plastic sheets have become essential in various industries. The global plastic sheet market was valued at approximately $65 billion in 2020. This number is projected to grow significantly, driven by demand in construction, packaging, and automotive sectors. Despite their advantages, the environmental impact of plastic remains a concern.

Plastic sheets come in various types, each suited for specific applications. For instance, polycarbonate sheets offer excellent durability. Acrylic sheets are favored for their clarity and lightweight nature. However, the production and disposal of these materials raise questions. Are we prioritizing functionality over sustainability?

Selecting the right plastic sheets involves understanding their properties. Some sheets resist UV radiation, while others are more flexible. It's essential to consider how these characteristics meet your needs. This guide aims to navigate the complexities of choosing the best plastic sheets for every use.

Overview of Plastic Sheet Materials and Their Properties

When it comes to plastic sheets, various materials serve distinct purposes. Polycarbonate is known for its high impact resistance, making it ideal for safety applications. It's five times stronger than glass, which is significant for many industries. Acrylic sheets, on the other hand, offer excellent clarity and UV resistance. This property makes them suitable for applications requiring visibility along with protection from sunlight.

Polyethylene sheets are lightweight and durable, often used in construction and packaging. They are resistant to moisture and chemicals, contributing to their popularity in various applications. The data from the Plastics Industry Association reveals that the global demand for plastic sheets will rise by 4% annually through 2027. It emphasizes the increasing versatility of these materials in several sectors.

Tip: When choosing plastic sheets, consider your application’s specific requirements. Evaluate properties like strength, clarity, and weight. This approach may prevent expensive mistakes. Sometimes, the cheapest option isn't the best for your needs.

Understanding the properties of different plastics can lead to informed choices. Mistakes are common due to a lack of knowledge about material characteristics. Researching thoroughly can save both time and money. Ensure you assess your needs carefully.

Common Uses of Plastic Sheets in Various Industries

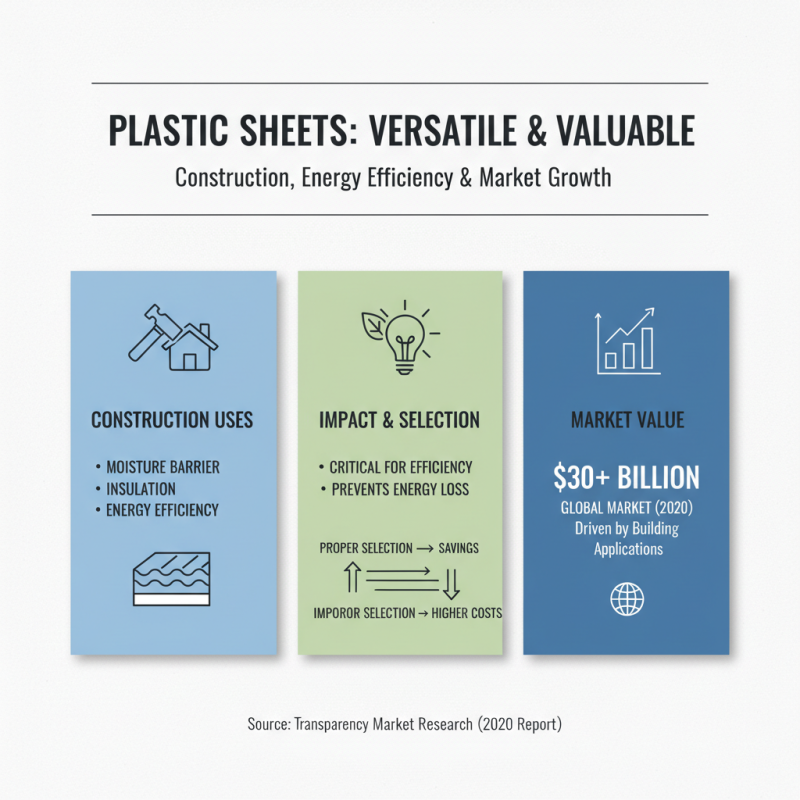

Plastic sheets are incredibly versatile materials used in a variety of industries. In construction, they serve as moisture barriers and insulation, playing a vital role in energy efficiency. According to a report from Transparency Market Research, the global plastic sheets market was valued at over $30 billion in 2020, reflecting a growing demand in building applications. However, not all plastic sheets are equally effective; improper selection can lead to significant energy loss and higher costs in the long run.

In the agricultural sector, plastic sheets are often used for greenhouse coverings and mulch films. These sheets help retain soil moisture and protect crops from harsh weather. The market for agricultural plastics is projected to reach $12 billion by 2026. However, sustainability is a concern. Many plastic materials take years to decompose, raising questions about environmental impact. More eco-friendly options are emerging, but their performance under various conditions still requires evaluation.

Additionally, in the medical field, plastic sheets are used for sterilization wraps and protective barriers. A recent study indicated that improper use can lead to contamination, undermining patient safety. The challenge remains in balancing convenience and safety, as well as exploring biodegradable alternatives. The evolution of material technology may offer improvements, but the transition needs careful consideration.

Factors to Consider When Choosing Plastic Sheets

When selecting plastic sheets, several factors come into play. Consider your intended use. Some projects require durability, while others prioritize flexibility. Thickness is important; it affects strength and rigidity. For example, a thickness range of 0.010 to 0.500 inches is common, depending on the application.

Temperature resistance can vary significantly among types. Some plastics withstand high heat, while others may warp. Know the environment your sheets will be exposed to. UV resistance is crucial if they will be outdoors. Many reports indicate that untreated plastics may degrade within a year under constant sunlight.

Tip: Always check the manufacturer's specifications for longevity and performance. Functionality matters, but aesthetics should not be overlooked. Color and transparency play a role in design.

Consider the ease of fabrication when choosing sheets. Some plastics are easier to cut and form than others. This is worth reflecting on. For intricate designs, choose sheets that allow for detailed work without fracturing. Cost is significant too, but it should not compromise quality. The right balance can lead to better long-term value.

2026 Best Plastic Sheets Comparison Chart

This chart compares the prices per square foot of different types of plastic sheets including Acrylic, Polycarbonate, PVC, PETG, and HDPE. This helps in understanding the cost implications when selecting the most suitable plastic sheet for various applications.

Top 2026 Plastic Sheet Products for Different Applications

Plastic sheets are versatile and used in various applications. For construction, polycarbonate sheets offer durability and impact resistance. They are ideal for roofs and skylights. Acrylic sheets, on the other hand, are great for interior design. Their clarity and lightweight nature make them perfect for displays.

In the signage industry, PVC sheets are popular choices. They can be printed on easily and come in different colors. Ideal for both indoor and outdoor use, they are often seen in advertisements. For crafts, HDPE sheets work well. They are food-safe and resistant to chemicals, making them great for projects.

While these options suit different needs, selecting the right type can be tricky. Consider thickness, transparency, and weight. Some users may buy without fully understanding their requirements. This could lead to wasted materials or unmet expectations. It's essential to reflect on your specific use case before making a decision.

Maintenance and Care Tips for Plastic Sheets

When it comes to maintaining plastic sheets, proper care can extend their lifespan significantly. Regular cleaning is essential. Use mild soap and water to wipe down surfaces. Avoid harsh chemicals that can cause damage. Rinse the sheets thoroughly to prevent residue build-up. For tough stains, a soft scrubber can be used, but be gentle. Over-scrubbing can lead to scratches.

Storage is another critical aspect. Plastic sheets should be kept in a cool, dry place. Avoid exposure to direct sunlight for long periods. UV rays can degrade the material over time. Consider using protective covers if the sheets are not in use. This simple step can prevent dust accumulation and scratches.

Sometimes, despite careful maintenance, issues arise. Warping can still occur due to temperature changes. If you notice unevenness, a little heat may help. Carefully applying heat can sometimes restore shape. However, this process requires precision. You want to avoid damaging the sheet. Understanding how your material responds to changes is vital. It's a learning curve.

Related Posts

-

10 Useful Tips for Choosing the Right Plastic Sheets for Your Project?

-

Top 10 Benefits of Plastic Molding for Your Manufacturing Needs

-

Exploring the Versatility of Cast Acrylic: Creative Applications for Modern Design

-

Top Plastic Parts Innovations in Modern Manufacturing?

-

The Ultimate Guide to Acrylic Plastic Top Types for 2025

-

10 Best Plastic Injection Techniques for Optimal Manufacturing Efficiency