Posts

How to Choose the Best Ball Screw for Sale?

Choosing the right ball screw for sale can significantly impact your project's success. Ball screws play a critical role in motion control applications. They ensure efficiency, precision, and longevity. However, many options exist, and selecting the best one requires careful consideration.

When evaluating ball screws, focus on specifications such as load capacity and accuracy. Look for trusted manufacturers who provide detailed technical data. It's essential to assess your system's requirements closely. Not all ball screws are created equal; some may not suit your needs perfectly.

As you explore ball screws for sale, consider potential trade-offs. A lower price may lead to compromised quality. Understanding the specific application will help avoid mistakes. Sometimes, the cheapest option may end up costing more in the long run. Recognize that each decision affects overall performance. Making the right choice requires time and reflection.

Understanding the Basics of Ball Screws and Their Applications

Ball screws play a critical role in converting rotary motion into linear motion. They are essential components in various applications, such as CNC machines, robotics, and automotive engineering. Understanding how ball screws function will help you choose the right one for your needs.

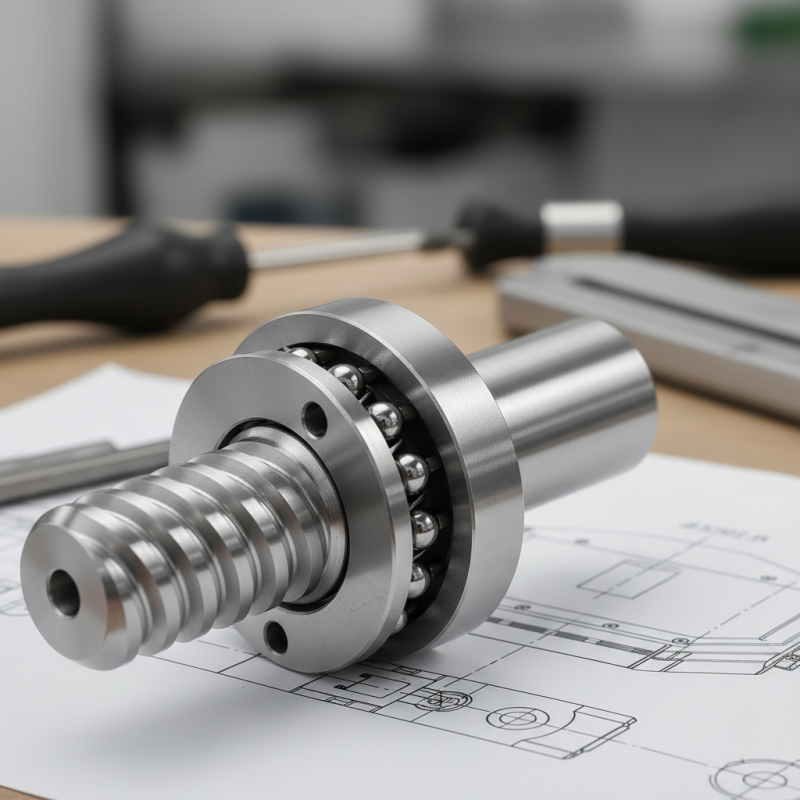

The structure of a ball screw consists of a screw spindle, a nut with ball bearings, and recirculation elements. The ball bearings enable smooth movement and reduce friction. When selecting a ball screw, consider factors like load capacity, accuracy, and efficiency. Each application has specific requirements that influence your selection. For example, precision applications may demand tighter tolerances.

It is crucial to reflect on your project’s needs. Are you prioritizing speed or precision? Each application might require different specifications. Sometimes, there is a temptation to opt for cheaper options, but that can compromise performance. Remember, investing in the right ball screw pays off in the long run.

Key Factors to Consider When Selecting a Ball Screw for Sale

When selecting a ball screw for sale, consider its load capacity. This factor determines how much weight it can handle effectively. Assess your specific application needs. A design that’s overly robust can be unnecessarily costly. Conversely, a weak screw could lead to failure and inefficiency.

Next, think about the screw's diameter and pitch. These dimensions affect speed and accuracy. A larger diameter can support heavier loads. A finer pitch improves accuracy, but may slow down speed. Balance is essential. You might have to compromise between speed and precision for your project needs.

Additionally, material quality matters. Common options include stainless steel and alloy steel. Each offers different strength and corrosion resistance levels. Look for the best fit for your environment. Evaluate how the ball screw will be used. Reflect on its operational conditions. Underestimating these factors can lead to disappointing results in performance and longevity.

How to Choose the Best Ball Screw for Sale? - Key Factors to Consider When Selecting a Ball Screw for Sale

| Factor | Description | Importance Rating (1-5) |

|---|---|---|

| Load Capacity | Maximum load the ball screw can withstand | 5 |

| Diameter | The outer diameter of the ball screw | 4 |

| Lead | Distance the nut moves with one screw revolution | 5 |

| Material | Type of steel used for durability | 4 |

| Accuracy | Precision of the ball screw’s movement | 5 |

| End Machining | Customization options for screw ends | 3 |

| Cost | Price range of the ball screw | 4 |

Evaluating Load Capacity and Performance Specifications

When choosing a ball screw, understanding load capacity is crucial. Each application has unique demands. Some machinery requires high precision, while others prioritize speed. Overloading a ball screw can lead to premature failure. Always assess the maximum load specifications provided by manufacturers. A ball screw must handle the expected forces without compromising performance.

Performance specifications also play an essential role. Speed is important but should not compromise accuracy. Look at the rotational speed and how it affects your application. Consider the environment too. Dust, humidity, and temperature can impact the performance of the screw. It’s worthwhile to question how these factors influence longevity and reliability. A high-performance ball screw might not be suitable in harsh environments.

Sometimes the ideal ball screw isn’t easy to find. You may need to experiment with different models and configurations. Don’t hesitate to reach out to experts for advice. Collecting feedback from users can guide your decision. Assessing long-term performance and maintenance needs is vital. It’s a process that may require adjustments and reevaluation, but that's part of finding the right fit.

Material and Construction Choices in Ball Screw Design

When selecting a ball screw, material and construction are key. The most common materials are steel and aluminum. Steel offers durability and strength, suitable for heavy loads. Aluminum is lightweight, useful in applications requiring less mass. However, aluminum may wear down faster in demanding environments.

The construction of a ball screw involves precision machining. Tolerances must be tight for optimal performance. If not, backlash can occur, leading to inefficiencies. Consider the thread profile too. A finer pitch increases accuracy but can reduce load capacity. This trade-off is crucial for applications needing precision.

Another aspect to think about is the surface finish. A smoother surface reduces friction but may be costlier. Regularly inspecting the ball screw for wear is also essential. Overlooking this can lead to failures. Each choice, from materials to design, impacts the longevity and efficiency of the ball screw. Users must evaluate their specific needs carefully.

Comparing Brands and Suppliers for Quality and Reliability

When choosing a ball screw, quality and reliability are paramount. Different suppliers have varying standards. It's essential to research their reputation. Customer reviews often provide insight. Look for feedback on durability and performance. Don't ignore the experiences of other users.

Pay attention to the materials used in the ball screw. High-quality materials ensure longevity. Check if the suppliers provide any guarantees or warranties. These can indicate the level of confidence a brand has in its products. Some manufacturers might cut corners to save costs, leading to unsatisfactory products.

Comparing prices is also vital. The most expensive option isn’t always the best. Sometimes, lower-priced items come from reputable suppliers offering good quality. Reflect on your specific needs before making a decision. Balancing price against performance can be challenging. It requires careful consideration of all available options.