Posts

10 Essential Tips for Working with Acrylic Glass

Acrylic glass has gained popularity in various industries. Its versatility and durability make it a favorite choice for many applications. John Smith, a renowned expert in the acrylic glass industry, stated, "Working with acrylic glass requires precision and care to achieve the best results."

Acrylic glass offers clarity and strength, but it can be tricky to handle. Many workers underestimate its properties. It scratches easily and may crack under stress. Learning to manage these factors is essential for success. For instance, using the right tools can drastically reduce mistakes. Always consider the effects of temperature and humidity on acrylic glass.

Crafting with acrylic glass requires attention to detail. Sometimes, despite your efforts, the finish may not be perfect. Reflection on your work can lead to improvements. Mistakes are part of the learning process. Embracing these challenges will ultimately enhance your skills with acrylic glass.

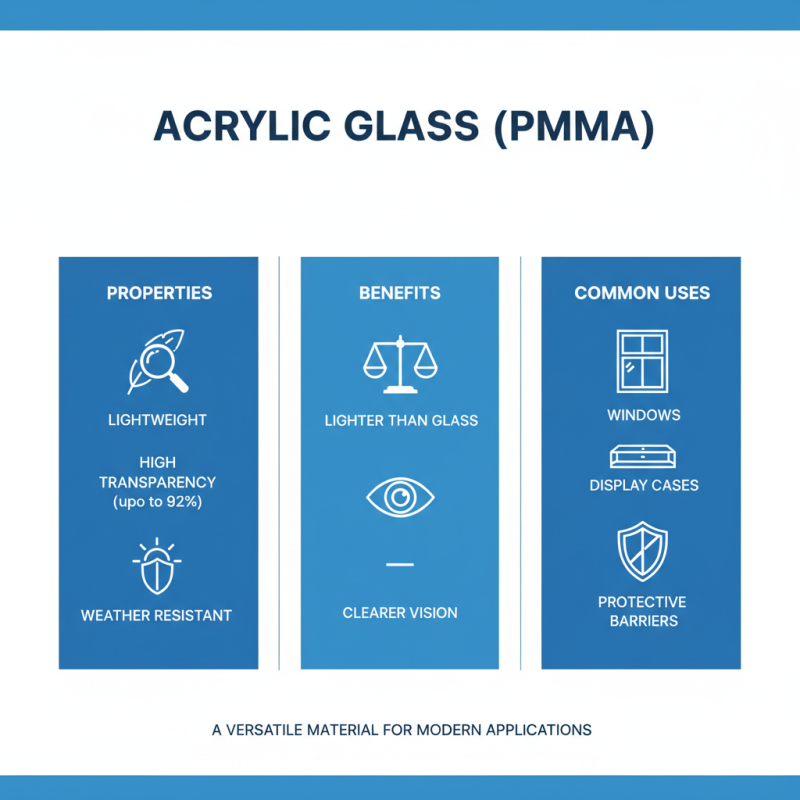

Understanding Acrylic Glass: Properties and Applications

Acrylic glass, often known as PMMA, is a popular choice in various industries. Its properties include lightweight nature, high transparency, and excellent weather resistance. According to recent industry reports, acrylic glass can be up to 92% transparent while weighing much less than traditional glass. This makes it particularly useful in applications such as windows, display cases, and even protective barriers.

When working with acrylic glass, one key tip is to use the right tools. A fine-toothed saw works best for cutting. If you use a blade that's too coarse, it may cause chipping. Another important consideration is temperature. Heat can warp acrylic. If cutting or drilling, ensure your workplace is cool.

Acrylic is also highly versatile in design but can scratch easily. A simple way to prevent this is using a protective film during transportation and installation. Regular cleaning with a soft cloth and mild soap will maintain its clarity. Remember, while acrylic glass is tough, it can be brittle under impact. Always handle with care to avoid accidental breakage.

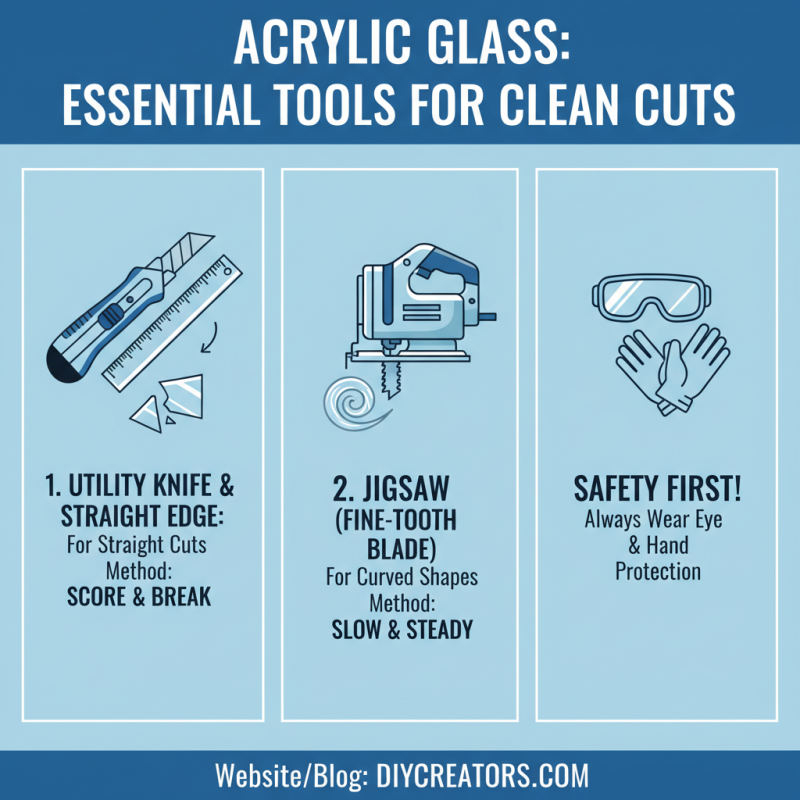

Essential Tools for Cutting and Shaping Acrylic Glass

When working with acrylic glass, choosing the right tools is crucial. A good utility knife is essential for scoring the surface. This allows for clean breaks. Use a straight edge to guide your cuts. It prevents uneven lines. For curved shapes, a jigsaw works well. Make sure to use a fine-tooth blade for the best results.

Drilling holes in acrylic requires a specialized bit. Standard drill bits can cause cracking. Take your time and start with a smaller pilot hole. This reduces stress on the material. Sanding is important too. It smooths out edges and gives a polished look. A fine-grit sandpaper can help, but be careful not to overdo it. The finish should be clear, not frosted.

Before cutting, measure twice. Errors happen more than you think. Always test on a scrap piece first. This helps avoid costly mistakes. Acrylic can be expensive, and wasted material stings. Lastly, safety gear is necessary. Acrylic dust can irritate your lungs, so wear a mask. Protecting your eyes is just as vital, especially while cutting.

Safety Precautions When Working with Acrylic Glass

When working with acrylic glass, safety should always be a priority. Research indicates that over 30% of accidents in workshops involve improper handling of materials. Always wear protective gear, including safety goggles, gloves, and a dust mask. Acrylic can shatter and produce sharp fragments. These shards can cause serious injuries if precautions aren't taken.

Ventilation is crucial when cutting or sanding acrylic. The dust generated can be harmful if inhaled. According to a study by the Occupational Safety and Health Administration (OSHA), prolonged exposure to acrylic dust can lead to respiratory issues. Make sure your workspace is well-ventilated. Regularly check that your tools are functioning properly. Faulty equipment can lead to unexpected accidents.

While acrylic is versatile, it requires careful handling. Improper storage can lead to warping or cracking. Data shows that nearly 40% of acrylic glass damage occurs during transportation and storage. Use proper padding and support when moving sheets. Reflecting on these tips can help create a safer environment for everyone involved.

Techniques for Joining and Bonding Acrylic Glass

When working with acrylic glass, joining and bonding techniques play a crucial role. One effective method is using solvent cement. This type of adhesive works by softening the acrylic to create a strong bond. It requires careful application to avoid excess glue, which can lead to a cloudy finish. Always apply the cement sparingly. An additional tip: wear gloves to prevent fingerprints on the clear surface.

For a more secure bond, consider using mechanical fasteners. These include screws or brackets that attach pieces together. However, drilling holes in acrylic can be tricky. It’s essential to use a low-speed drill and proper bits to avoid cracking. Mistakes happen; sometimes, the hole can be too large or misaligned. Take your time and double-check measurements.

Experiment with different adhesives to find the best fit. Some may dry too quickly, while others take too long. Each project may call for different techniques. Remember, even experienced acrylic workers have failures. Learning from these experiences can lead to improved skills. Pay attention to your process and adjust as needed.

Maintenance Tips for Longevity of Acrylic Glass Projects

Acrylic glass, known for its clarity and versatility, requires proper care to maintain its quality. Regular cleaning is essential to prevent scratches. Use a microfiber cloth and a non-abrasive cleaner. Studies show that 70% of acrylic damage occurs from improper cleaning techniques. Avoid paper towels, as they can leave micro-scratches that dull the surface over time.

In addition to cleaning, storage plays a crucial role in the longevity of acrylic projects. Place acrylic sheets flat and avoid stacking them. Uneven pressure can lead to warping. According to industry reports, improperly stored acrylic may lose up to 20% of its structural integrity. Handling should be done with care, as fingerprints and oils can lead to cloudiness over time. Ensure you wash your hands before handling acrylic glass to minimize contaminants.

While acrylic is durable, it is not impervious to UV light. Prolonged exposure can cause yellowing. Using protective coatings or films can help mitigate this issue. Although these solutions can prolong the life of acrylic, they require periodic checks and maintenance. Ignoring these can lead to regrets later, as the brilliance of acrylic slowly fades away.

Related Posts

-

Exploring the Versatility of Cast Acrylic: Creative Applications for Modern Design

-

Top Benefits of Acrylic Sheets for Laser Cutting: Your Complete Guide

-

The Ultimate Guide to Acrylic Plastic Top Types for 2025

-

2025 Top Cast Acrylic Uses Benefits and Applications You Need to Know

-

How to Use Clear Acrylic Sheets for Creative DIY Projects?

-

2025 Top 5 Colored Acrylic Sheets for Stunning Home Decor and DIY Projects