Posts

What is Thick Plastic Sheets and Their Uses?

Thick plastic sheets have become essential in various industries. According to a recent report by MarketsandMarkets, the global demand for plastic sheets is expected to reach $45 billion by 2027. These versatile materials offer unique advantages, including impact resistance, durability, and weather resistance.

Industries such as construction, agriculture, and manufacturing heavily rely on thick plastic sheets. In construction, they serve as protective barriers and vapor retarders. In agriculture, they function as ground covers or greenhouses. These applications highlight their importance, yet issues with sustainability persist. Many producers focus on profits, overlooking environmental impacts.

Some products on the market may not adhere to eco-friendly practices. This raises questions about quality and long-term effects. Consumers should assess both performance and environmental footprint when choosing thick plastic sheets. Balancing utility with sustainability is crucial for future advancements in the industry.

Definition and Composition of Thick Plastic Sheets

Thick plastic sheets are versatile materials widely used across various industries. These sheets typically contain high-density polyethylene (HDPE), polyvinyl chloride (PVC), or acrylic. The composition varies, affecting durability, flexibility, and resistance. The thickness often ranges from 0.5mm to several centimeters. This variation allows for different applications.

Many people overlook the numerous uses of thick plastic sheets. They serve as protective barriers in agriculture, construction, and even in art projects. In packaging, they provide strength and protect against the elements. However, not all thick plastic sheets are created equally. Some may not withstand UV exposure, leading to degradation. It is essential to consider specific environmental factors when selecting materials.

While thick plastic sheets offer many benefits, their environmental impact cannot be ignored. Disposal and recycling can be problematic. Many facilities struggle to process plastic waste appropriately. This raises questions about sustainability. Exploring biodegradable alternatives may be necessary. Understanding the limitations and challenges is crucial for responsible usage.

Key Characteristics and Properties of Thick Plastic Sheets

Thick plastic sheets are versatile materials with unique characteristics. These sheets, often made from polycarbonate, acrylic, or PVC, are prized for their strength and durability. According to a 2021 market analysis, the global demand for thick plastic sheets is projected to reach over $10 billion by 2025. This growth reflects their diverse applications across various industries.

One key property of thick plastic sheets is their impact resistance. This quality makes them suitable for safety applications, such as protective barriers in factories or transparent shields in public spaces. A study indicates that polycarbonate sheets can withstand impacts up to 200 times greater than glass. Additionally, they exhibit excellent weather resistance, ensuring longevity in outdoor settings. Thickness can vary, typically ranging from 0.125 to 0.5 inches, impacting weight and strength.

Moreover, thick plastic sheets can be challenging to work with. They may require specialized cutting tools to achieve precise dimensions. Some users report difficulty in handling large sheets due to their weight. Data shows that improper installation can lead to susceptibility to warping or cracking over time. Understanding these nuances is vital for optimizing their use in projects. Proper handling and installation are crucial for maximizing their benefits while minimizing potential drawbacks.

Common Applications of Thick Plastic Sheets in Various Industries

Thick plastic sheets are increasingly valuable in several industries. These sheets often find applications in construction, automotive, and packaging. In construction, they act as barriers against moisture and air. They are versatile, durable, and lightweight. Reports show that the construction industry demand for thick plastic sheets has surged by 25% over the last four years.

In the automotive sector, thick plastic sheets serve as protective liners and interior panels. They help in noise reduction and are a cost-effective solution. A study indicated that the use of such materials can reduce manufacturing costs by approximately 15%. However, challenges remain. Some manufacturers struggle with the recycling of these materials, raising environmental concerns.

In packaging, thick plastic sheets provide a robust protective layer. They preserve food and extend shelf life. According to industry analysts, the demand for such packaging is projected to increase by 30% over the next decade. Yet, the reliance on single-use plastics complicates sustainability efforts. This industry must innovate for a greener future while meeting growing demands.

Market Trends: Growth and Demand for Thick Plastic Sheets

Thick plastic sheets have gained notable traction in various industries. The market for these sheets is expected to grow significantly, with a projected compound annual growth rate (CAGR) of 4.5% over the next five years. For many applications, thick plastic sheets offer durability, flexibility, and resistance to environmental factors.

The construction sector is a major driver of demand. These sheets are used for insulation, protective barriers, and even flooring. According to a recent industry report, over 30% of thick plastic sheets are utilized in construction projects. Commercial uses are also growing. For instance, the packaging industry increasingly opts for thick plastic for its protective qualities. Yet, challenges remain. Recycling thick plastic can be more complicated than lighter alternatives.

**Tip:** When selecting thick plastic sheets, consider their specific applications. This ensures optimal performance and longevity.

Another area of growth is the agricultural sector. Farmers find thick sheets useful for greenhouse coverings and mulch films. Some farms even use them to protect crops from harsh weather. The rising demand for sustainable practices complicates things, however. Many companies are exploring biodegradable options, which are not yet mainstream.

**Tip:** Always research material properties before purchase. Understanding the grades available helps in making informed decisions.

What is Thick Plastic Sheets and Their Uses? - Market Trends: Growth and Demand for Thick Plastic Sheets

| Application | Material Type | Thickness (mm) | Market Growth Rate (%) | Key Benefits |

|---|---|---|---|---|

| Construction | Polycarbonate | 3-10 | 6% | Durability, Weather Resistance |

| Signage | Acrylic | 2-25 | 8% | Clarity, Versatility |

| Packaging | Polyethylene | 1-15 | 5% | Lightweight, Cost-Effective |

| Automotive | PVC | 2-10 | 7% | Impact Resistance, Flexibility |

| Furniture | Polypropylene | 2-30 | 4% | Customization, Ease of Maintenance |

Environmental Considerations and Recycling of Thick Plastic Sheets

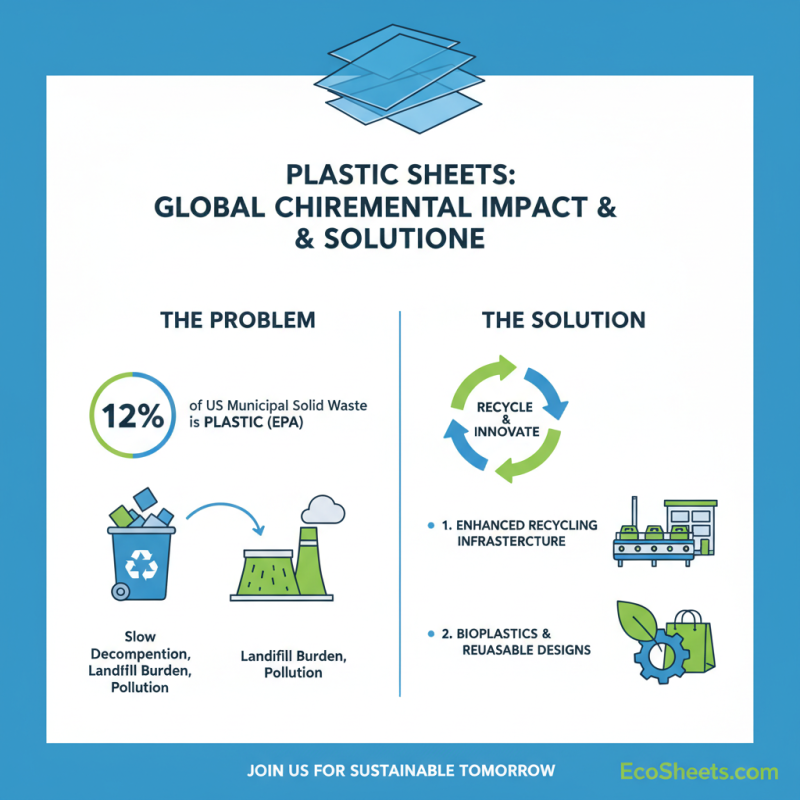

Thick plastic sheets, often made from materials like polyethylene or polycarbonate, play a significant role in various industries. However, their environmental impact cannot be overlooked. According to the Environmental Protection Agency, plastic accounts for about 12% of municipal solid waste in the U.S. annually. This calls for better recycling solutions to ensure a sustainable future.

Recycling thick plastic sheets remains a challenge. While some facilities can process these materials, the recycling rates are still low. A study from the Plastics Industry Association indicates that less than 15% of plastic waste is actually recycled. Many thick plastic sheets are not collected in curbside programs. As a result, they often end up in landfills or the ocean. This leads to long-lasting environmental consequences that harm wildlife and ecosystems.

Efforts are being made to promote the recycling of thick plastic sheets. Innovative technologies are emerging to convert plastic waste into new materials. However, consumers need to take responsibility as well. Selecting products made from recycled plastic can help close the loop. The path to sustainability is still unclear, but raising awareness is key to addressing these pressing issues.

Related Posts

-

2026 Best Plastic Sheet Cut to Size Options for Your Projects?

-

10 Essential Tips for Acrylic Fabrication Success in 2023 Based on Industry Data

-

2025 Top Cast Acrylic Uses Benefits and Applications You Need to Know

-

How to Get Plexiglass Cut to Size for Your Projects and DIY Ideas

-

What is Plastic Prototype Manufacturing? Benefits and Key Processes Explained

-

Top Benefits of Acrylic Sheets for Laser Cutting: Your Complete Guide