Posts

Top 10 Best Plastic Injection Molding Techniques for Efficient Manufacturing?

The plastic injection molding industry has seen rapid advancements in recent years. According to a report by MarketsandMarkets, the market is projected to reach $339.7 billion by 2025, growing at a CAGR of 5.2%. This growth highlights the increasing demand for efficient manufacturing techniques in various sectors, from automotive to consumer goods.

Expert in the field, Dr. Jane Smith, emphasizes the importance of innovation in plastic injection molding. She states, "Adapting new techniques is crucial for staying competitive in this evolving market." As businesses strive to enhance productivity, understanding the top plastic injection molding techniques is essential.

Many companies still rely on traditional methods, which may not maximize efficiency. The challenge lies in balancing cost and quality while embracing new approaches. Continuous improvement is necessary, as manufacturers must reevaluate their practices to thrive in a changing landscape. The insights gained from exploring diverse techniques can steer businesses toward more sustainable growth.

Overview of Plastic Injection Molding Techniques

Plastic injection molding is a crucial technique in modern manufacturing. It allows for the mass production of precise parts quickly. Industry data indicates that about 30% of all plastic products are made using this method. The process involves injecting molten plastic into a mold, where it cools and solidifies into the desired shape.

Various techniques enhance efficiency in injection molding. Hot runner systems, for example, can reduce waste, as they keep the plastic molten until it is injected. A study showed that implementing these systems can decrease material waste by up to 15%. Additionally, multi-cavity molds can produce several identical parts simultaneously, further speeding up production rates.

However, challenges persist. Quality control is often overlooked, leading to defects. A report from a leading manufacturing association stated that nearly 20% of injected parts require reworking. This issue highlights the importance of investing in proper training and quality assurance measures. It’s essential for manufacturers to constantly evaluate their processes.

Key Considerations for Efficient Plastic Injection Molding

Efficient plastic injection molding is crucial for manufacturers aiming for high productivity and quality. Key considerations include material selection, mold design, and processing parameters. According to Plastics Technology, 30% of production costs stem from inefficient molding practices. This emphasizes the need for a strategic approach.

A crucial tip is to ensure proper temperature control. Maintaining the right temperature can reduce cycle times significantly. Studies suggest that a temperature variance of just 5 degrees Celsius can lead to inconsistencies in product quality. Therefore, investing in precise heating and cooling systems is worthwhile.

Another important aspect is mold maintenance. Regular inspection and maintenance can mitigate unexpected downtimes. Research indicates that 15% of production delays are attributed to mold issues. Encouraging a culture of proactive maintenance can lead to higher efficiency and output quality over time. Always seek feedback from manufacturing teams to identify potential areas for improvement.

Rapid Prototyping in Injection Molding

Rapid prototyping in injection molding is a game changer for manufacturers.

It allows for the quick creation of parts before full-scale production begins. This process not only saves time

but also reduces costs significantly. By utilizing

3D printing or CNC machining, companies can

create prototypes that are close to the final product. This enables design adjustments to be made early,

leading to better overall results.

When engaging in rapid prototyping, keep a few tips in mind. Select materials that mimic your final product's

properties. This will provide a more accurate representation. Additionally, focus on the design complexity.

Sometimes, overly intricate designs can lead to difficulties during the molding phase. It's essential to

balance aesthetics with practicality.

Remember that not every prototype is perfect. Often, these initial designs reveal flaws. This is an

opportunity for improvement rather than a setback.

Embracing this mindset fosters innovation and leads to better products. For efficient manufacturing,

iterative testing through rapid prototyping is invaluable.

Make adjustments and strive for refinement; this is the key to success.

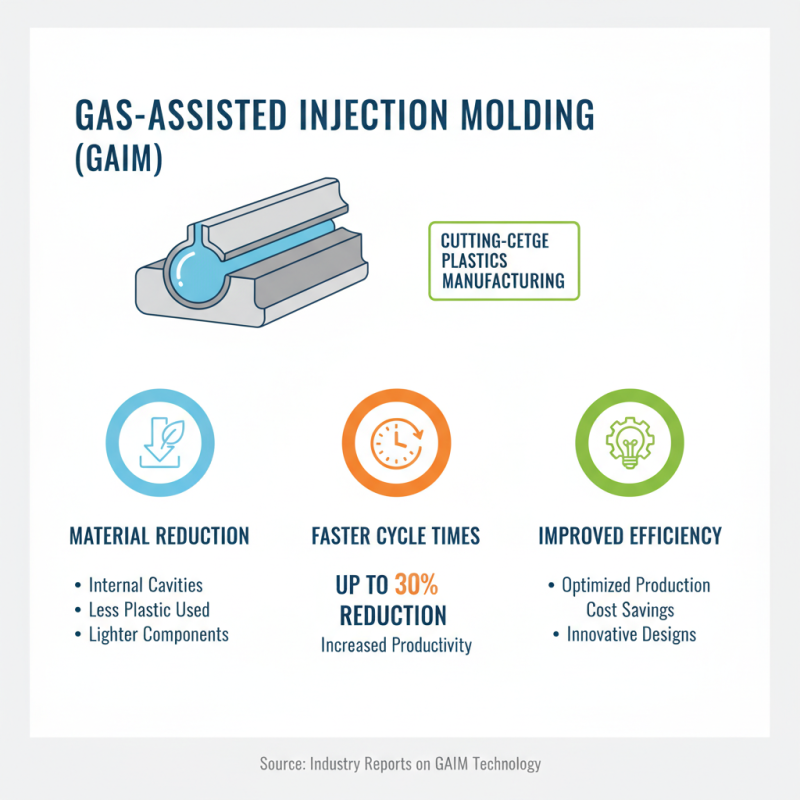

Gas-Assisted Injection Molding Techniques

Gas-assisted injection molding (GAIM) is a cutting-edge technique in the plastic manufacturing industry. This method utilizes gas to create internal cavities within plastic parts. It reduces material usage and leads to lighter components. Reports indicate that GAIM can cut cycle times by up to 30%. This efficiency is crucial for companies looking to improve productivity.

The process starts with conventional injection molding methods. However, once the molten plastic fills the cavity, gas is injected. This pressure helps push the plastic against the mold walls. It results in a more uniform wall thickness. Yet, GAIM isn't perfect. It may introduce complexities in mold design. Manufacturers must invest in specialized molds and gas delivery systems. As a result, initial costs can be high.

Despite the benefits, there are challenges. Issues like gas escape can lead to defects. Gas must be precisely controlled for quality. According to industry studies, defects can still occur in 5-7% of parts produced. Companies must monitor every stage closely to minimize waste. Precision remains key in attaining desired outcomes, but variations in gas control can complicate this process.

Two-Shot and Multi-Shot Injection Molding Explained

Two-shot and multi-shot injection molding are advanced techniques in plastic manufacturing. They allow for the production of complex parts with multiple materials or colors. This process is efficient and reduces the need for additional assembly. In two-shot molding, two different materials are injected into a single mold. This creates a single part that combines the properties of both materials. For instance, a hard plastic with a soft grip area can be produced seamlessly.

Multi-shot molding takes this further. It involves injecting three or more materials or colors in one cycle. This creates intricate designs and enhances functionality. The process can produce parts with various surface finishes, textures, and rigidities. However, it’s not without challenges. The mold design is more complex, requiring precise engineering to ensure proper alignment. Additionally, material compatibility must be carefully considered. Poor choices can lead to defects and costly errors. These techniques require significant investment but can yield impressive results when executed properly.

Top 10 Best Plastic Injection Molding Techniques

FAQS

: Regular exercise can improve cardiovascular health and enhance mood. It may also boost energy levels and reduce stress.

Adults should aim for at least 150 minutes of moderate exercise weekly. This can be broken into shorter sessions.

Yes, most people can start exercising. However, consulting with a healthcare professional is wise before beginning any new program.

Beginners may benefit from walking, cycling, or swimming. These activities are low-impact and easy to incorporate.

Setting achievable goals and tracking progress can help maintain motivation. Finding a workout buddy may also make it enjoyable.

Yes, mild soreness is common after workouts. It usually indicates that muscles are adapting. However, sharp pain should be monitored.

Conclusion

Plastic injection molding is a vital manufacturing process that utilizes various techniques to enhance efficiency and product quality. This article explores the top methods, beginning with an overview of different plastic injection molding techniques, emphasizing the importance of selecting the right method based on production needs. Key considerations for efficient plastic injection molding include optimizing design and mold quality, while rapid prototyping enables faster iterations and improved designs.

Additionally, advanced techniques such as gas-assisted injection molding and two-shot molding are discussed, showcasing their advantages in producing complex parts with reduced cycle times. The use of advanced materials further expands the capabilities of plastic injection molding, allowing for more durable and lightweight products. Finally, implementing robust quality control practices ensures consistency and reliability in the final output, making plastic injection molding a cornerstone of modern manufacturing.

Related Posts

-

How to Choose the Best Plastic Injection Molding Process for Your Project

-

Mastering the Injection Molding Process: Tips for Streamlining Production Efficiency

-

How to Optimize Plastic Parts Manufacturing for Efficiency and Quality

-

10 Best Plastic Injection Techniques for Optimal Manufacturing Efficiency

-

2025 Guide: How to Get Plexiglass Cut to Size for Your Projects

-

Top 10 Benefits of Plastic Molding for Your Manufacturing Needs