Posts

10 Useful Tips for Choosing the Right Plastic Sheets for Your Project?

In the realm of construction and design, selecting the right materials can be daunting. Plastic sheets present a versatile solution for numerous projects, from DIY crafts to industrial applications. Expert Mark Johnson emphasizes, "Choosing the right plastic sheets can significantly impact the success of your project."

Understanding the different types of plastic sheets is crucial. Acrylic, polycarbonate, and PVC sheets each serve distinct functions. Acrylic sheets, for example, are highly transparent and durable, ideal for display cases. In contrast, polycarbonate sheets are more robust and impact-resistant, perfect for protective barriers. Not all plastic sheets are created equal, and that can lead to confusion.

Reflection is also needed when selecting these materials. Overlooking specific requirements could lead to unexpected costs or project delays. Striking the right balance between price and quality is vital. Be mindful of project needs and environmental conditions. With the right guidance, you can choose not just any plastic sheets, but the perfect ones for your project.

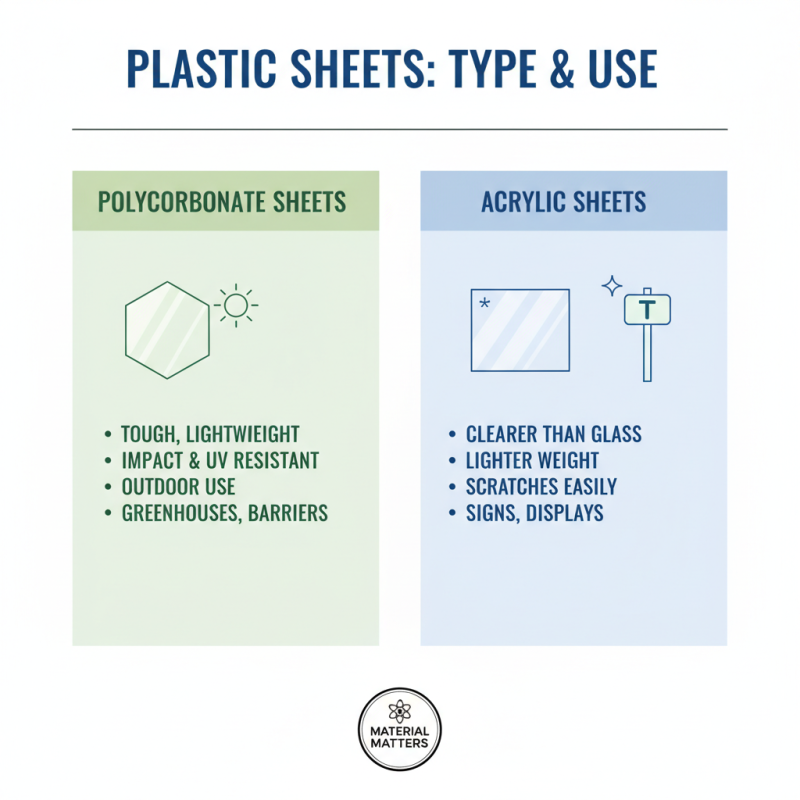

Understanding Different Types of Plastic Sheets and Their Applications

When selecting plastic sheets for a project, understanding the different types is vital. Polycarbonate sheets are tough yet lightweight. They resist impact and UV rays. This makes them ideal for outdoor applications. Consider them for greenhouses or protective barriers. Acrylic sheets are another option. They are clearer than glass and lighter too. However, they can scratch easily. They work well for signs or displays.

Polyvinyl chloride (PVC) sheets offer excellent chemical resistance. They are suitable for equipment covers and plumbing applications. Keep in mind that they are less flexible. This might restrict their use in some designs. High-density polyethylene (HDPE) sheets are durable and easy to clean. Use them in food processing or industrial settings. But, don’t expect them to handle high temperatures well.

Choosing the right plastic sheet requires careful thinking. You may find the perfect sheet only to discover it doesn't fit your needs. Always consider strength, flexibility, and transparency. It’s common to underestimate these factors. Reflect on your project's demands. Balancing aesthetics and functionality can be a challenge.

Factors to Consider When Selecting Plastic Sheets for Your Project

When selecting plastic sheets for your project, several factors come into play. First, consider the thickness of the sheets. Thicker sheets offer durability but may be harder to work with. A project that requires flexibility will benefit from thinner options. Understanding the environment where the sheet will be used is crucial. Will it be exposed to high temperatures or chemical substances? These conditions will guide your choice.

Another important aspect is the transparency of the sheets. While some projects might need clarity, others may require frosted or opaque finish. Aesthetics can matter too, especially if the final product is visible. Reflect on how the sheet's color and finish align with your project's vision. Additionally, consider ease of installation. Some sheets may need special tools or adhesives, which can complicate the process.

Lastly, budget constraints are a practical concern. While it’s tempting to opt for cheaper materials, they might come with hidden drawbacks. Weigh the costs against the benefits of higher-quality options. Reflect on whether saving money upfront could lead to more expenses down the line. Balancing these factors will help you make a more informed decision.

Evaluating Thickness and Durability Requirements for Plastic Sheets

When selecting plastic sheets, thickness and durability are crucial factors. A thicker sheet generally offers better durability. For instance, a sheet that is ¼ inch thick can endure heavy impacts better than a 1/16 inch sheet. However, thicker materials can weigh more and may be harder to handle. Consider how the weight will affect your project.

Evaluate the environment where the plastic sheet will be used. If it’s exposed to UV light, look for options that resist degradation. A sheet that appears sturdy may not withstand extreme heat or cold. Check the temperature range for your chosen material. Make sure it fits your project needs.

Sometimes, the appearance of durability can be misleading. A clear sheet may look tough but can crack easily. Always request samples or perform tests to be sure. You might find that a lesser-known material performs just as well, or even better. It’s worth the effort to explore various options.

Assessing Cost-Effectiveness and Budget Constraints for Your Plastic Sheets

When selecting plastic sheets, cost-effectiveness is critical. A recent industry report revealed that up to 30% of project budgets can be allocated to materials like plastic sheets. Understanding material properties and pricing can help streamline costs. Clear polycarbonate sheets, for instance, are durable but may come at a premium. Yet, they could save money in the long run due to their longevity.

Budget constraints often force tough decisions. It might be tempting to opt for cheaper materials to cut costs, but this could lead to more expenses later. A study showed that low-grade plastic sheets may need replacement every few years, increasing costs over time. Balancing initial expenses against potential long-term investments should be a priority.

It is essential to evaluate your project requirements thoroughly. Consider the functions plastic sheets must perform. Can a less costly option still meet your needs? Revisiting your project's purpose can uncover more cost-effective choices. Sometimes, the cheapest option leads to compromising quality. Be wary of overly tight budgets that ignore potential performance issues.

Tips for Sourcing Quality Plastic Sheets from Reputable Suppliers

When sourcing quality plastic sheets, starting with reputable suppliers is essential. Look for suppliers with a good track record. Check for reviews and testimonials online. Many websites provide insights into customer experiences. Direct communication is also vital. Reach out with questions about their products, expertise, and service. A reliable supplier is often willing to share information about their sourcing and production processes.

Consider visiting local distributors. This allows for a physical inspection of the sheets. You can gauge the quality first-hand. Be cautious, though—some sheets may look good but lack durability. Ask for samples if possible. This can help ensure the material meets your project's specific needs. Also, engage with industry professionals for recommendations. They often have insights into which suppliers consistently deliver high-quality products.

Remember, not every supplier is created equal. It’s easy to overlook details in the sourcing process. Focus on the material’s specifications. Different applications require distinct qualities. Reflect on the specific requirements of your project. The right choice of plastic sheet can make all the difference. Research thoroughly and don’t rush the decision. Your project's success may depend on it.

Related Posts

-

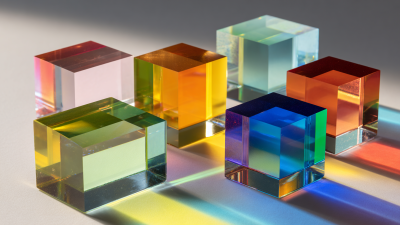

The Miracle of Cast Acrylic Unveiling Its Versatile Applications in Modern Design

-

What is a plastic molding machine and how does it work?

-

Top 10 Benefits of Plastic Molding for Your Manufacturing Needs

-

Revolutionizing Product Design with Advanced Plastic Prototype Manufacturing Techniques

-

2025 Top 5 Colored Acrylic Sheets for Creative Projects and Designs

-

2025 Top 5 Colored Acrylic Sheets for Stunning Home Decor and DIY Projects